|

|

What is J-STD-001ES?

Purpose: J-STD-001ES (an addendum to J-STD-001E) provides requirements to ensure the reliability of soldered electronic assemblies that must survive the vibration and thermal cycle environments getting to and operating in space.

J-STD-001ES is not a standalone module; it in fact is part of J-STD-001E and cannot be used with any previous versions of J-STD-001.

J-STD-001ES builds upon and in some cases overrides (takes precedence over) the Class 3 requirements of J-STD-001E. (Class 3 is the designation for high performance or life critical electronics)

Space electronics hardware will be exposed to rigorous thermal cycles and intense vibration during acceptance and/or qualification testing, as well as during launch and mission life.

The Specifics:

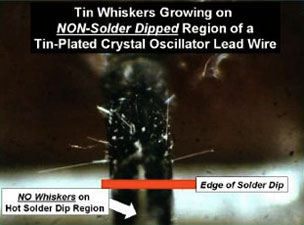

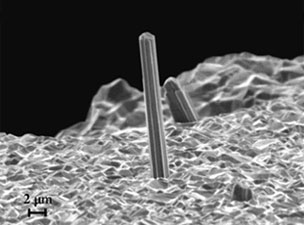

A major concern for space electronics is tin whiskers. Tin whiskers are electrically conductive, crystalline structures of tin that sometimes grow from surfaces where tin (especially electroplated tin) is used as a final finish. Tin whiskers have been observed to grow to lengths of several millimeters (mm) and in rare instances to lengths in excess of 10 mm. Numerous electronic system failures have been attributed to short circuits caused by tin whiskers that bridge closely-spaced circuit elements maintained at different electrical potentials. The presence of lead in solder greatly reduces the growth of tin whiskers.

Examples of Tin Whiskers |

For this Addendum, lead-free tin is defined as tin containing less than 3 percent lead by weight as an alloying constituent.

According to J-STD-001 ES the following shall be prohibited unless documented and controlled through a User approved Lead Free Control Plan (LFCP).

- Lead-free Tin platings, metallization, etc., on external surfaces of parts

- Any components and printed circuit assemblies (PCAs), etc. assembled with lead-free tin solder alloys except Sn96.3 Ag3.7

Components and sub-assemblies identified as having lead-free tin surfaces shall be protected by at least two process techniques to reduce or eliminate the risks created by metallic whisker formation in the expected end-use application/environment.

Another concern in space electronics is Red Plague – a common term for cuprous or cupric oxide corrosion. It can occur in silver-coated soft or annealed copper conductors, such as component leads, single and multi-stranded wires and PCB conductors. It can develop between the copper base metal and the silver coating in the presence of moisture (H2O) and oxygen (O2). The use of silver-coated copper conductors shall require the implementation of a User-approved Red Plague Control Plan.

Solder: Solder alloys shall be Sn60Pb40, Sn62Pb36Ag2, Sn63Pb37, or Sn96.3Ag3.7.

To minimize the possibility of gold embrittlement, gold shall be removed from at least 95% of the surface to be soldered of all component leads, component terminations, and solder terminals.

- J-STD-001ES requires that the Manufacturer develop and maintain operating procedures that shall include:

- Flux and solder paste application

- Drying/degassing

- Preheating

- Controlled atmosphere

- Solder reflow operation

- Cooling operation

- Reflow profile

Inspection: Surfaces cleaned shall be inspected between 4X and 10X magnification and shall be free of visual evidence of residue or contaminants

Staking or epoxy bonding of components to the printed circuit board shall be identified on the assembly drawing. Some component packages should always be staked (e.g., axial leaded solid-slug tantalum capacitors).

Below are some of the basic requirements for J-STD-001E

J-STD-001 Certified Solderers are trained 40 hours for the proper soldering techniques that ensure high reliability of solder joints for high performance electronics.

Solder purity and flux requirements adhere to J-STD-006 and J-STD-004 respectively.

J-STD-001 has cleanliness requirements that are specified and met.

J-STD-001 requires Moisture Sensitive Devices (MSDs) to be handled according to J-STD-033 specification with a controlled procedures.

Basic PCB acceptability requirements are specified according to IPC-A-600.

The manufacturer shall maintain operating procedures describing the soldering process and the proper operation of the automatic soldering machine and associated equipment.

Statistical Process Control (SPC). In a J-STD-001 compliant facility, SPC is used in SMT reflow and wave soldering processes.

A J-STD-001 compliant facility requires Ball Grid Array (BGAs) to be evaluated by X-Ray images to allow assessment of the characteristics specified for dimensional and solder fillet requirements.